Published on June 1, 2025 by Sharmeehouse

Custom ceramic mugs are powerful tools for brand visibility. Discover how Sharmeehouse uses them to create lasting impressions through sustainable materials, strategic design, and personalized branding that aligns with modern marketing goals.

1. Ceramics: A Durable, Sustainable Branding Medium

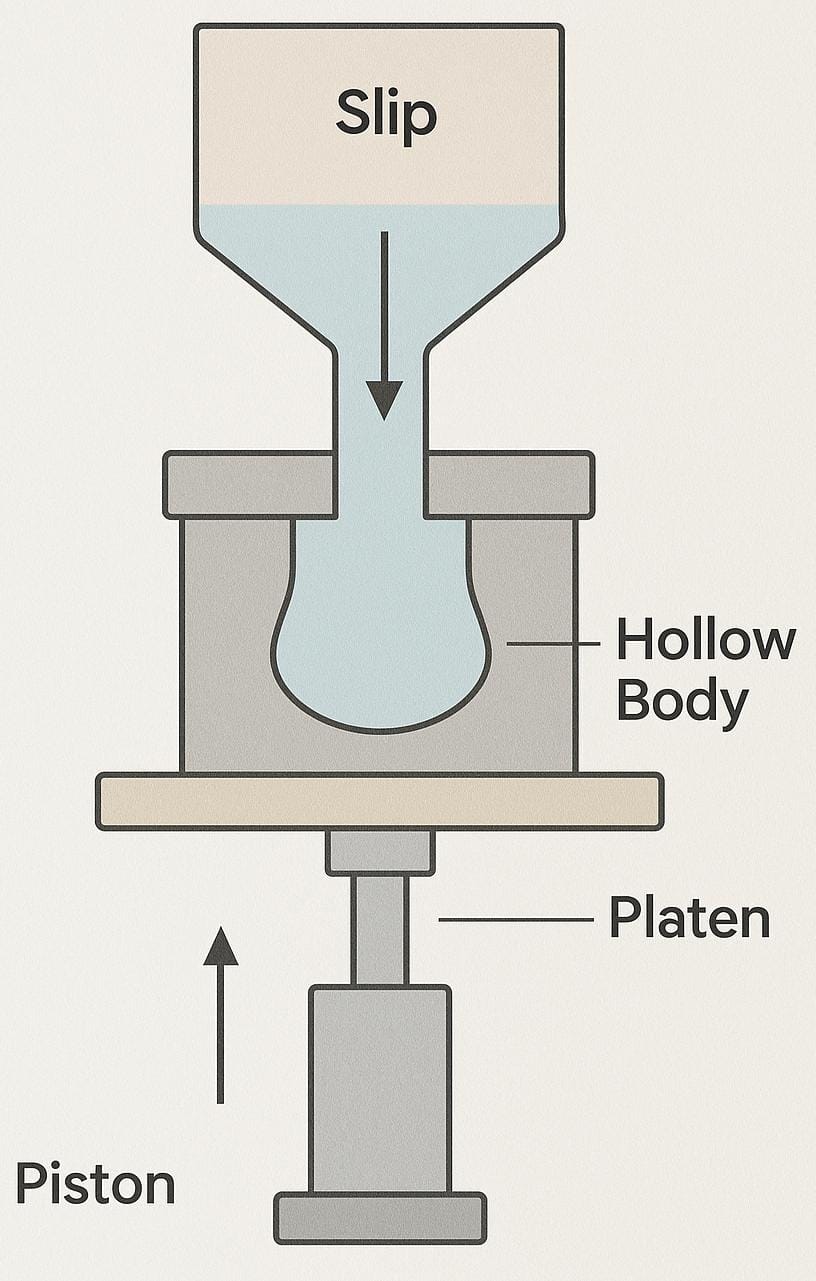

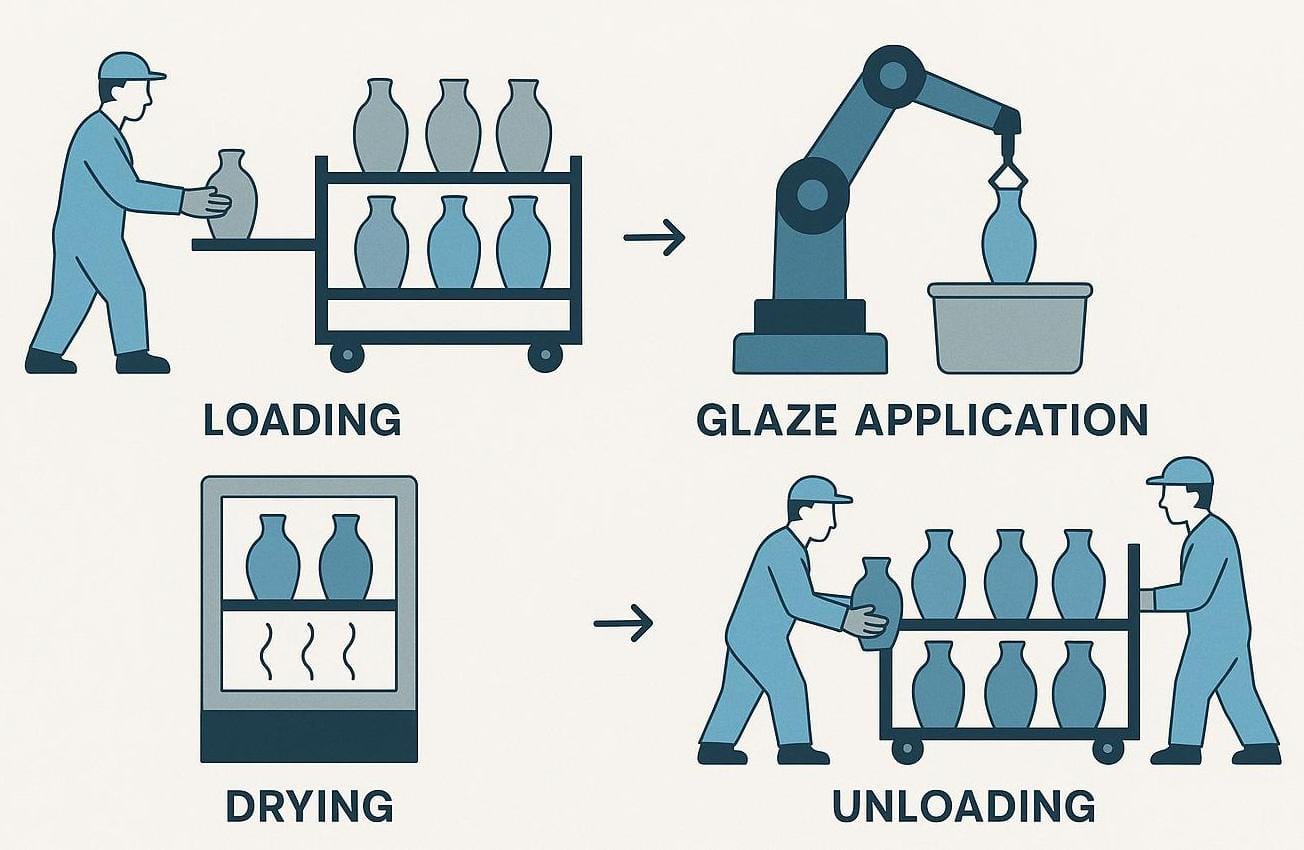

Unlike plastic or paper promotional products, ceramic mugs offer unmatched material longevity. Fired at over 1,000°C, stoneware and porcelain mugs resist fading, staining, and cracking, ensuring your logo or message remains intact even after hundreds of washes.

Thanks to modern glazing techniques, full-color prints can now bond chemically to ceramic surfaces. This permanence adds credibility to your brand and communicates a commitment to quality and sustainability.

2. High Visibility, High Frequency

The average person consumes 2–4 cups of coffee or tea daily. A branded ceramic mug placed on a desk or in a breakroom gains thousands of impressions per year—not just by the mug’s user, but by surrounding colleagues. This consistent exposure reinforces brand recall far better than fleeting digital ads.

3. Customization Enhances Emotional Engagement

Custom mugs offer more than just logo placement. Brands now personalize mugs with:

- Employee names or job titles

- Special event themes (e.g., product launches or company anniversaries)

- Seasonal or limited-edition messages

This level of personalization boosts perceived value, making people more likely to keep and use the mug regularly. According to a 2024 PPAI study, 83% of consumers could recall the brand on promotional drinkware they had received.

4. Cross-Industry Appeal

Custom ceramic mugs are versatile across multiple industries:

- Hospitality: Reinforce a premium image in cafes and hotels.

- Corporate: Ideal for onboarding kits or client thank-you gifts.

- Retail: Artistic mugs with minimal branding sell well in lifestyle shops.

- Nonprofits & Education: Promote sustainable values with functional merchandise.

5. Eco-Conscious Messaging Built-In

Ceramic mugs are inherently sustainable. Reusable, recyclable, and often produced with non-toxic glazes, they align naturally with brands that prioritize eco-conscious values. Replacing disposable cups with branded ceramic mugs also supports internal green initiatives.

6. Why Sharmeehouse?

At Sharmeehouse, we combine expert ceramic craftsmanship with brand strategy. Our mugs are more than just functional—they are visual ambassadors of your message. Whether you’re preparing for an event, curating a retail shelf, or gifting your internal team, our solutions ensure your brand stays memorable—sip after sip.

Looking to create custom ceramic mugs for your brand? Contact us today to request a quote or sample.